Hy-Capacity PPE Efforts

Hy-Capacity's Story:

Toward the end of March, we started to hear about the potential shortages of PPE and started seeing posts on social media on how to make cloth masks at home. At the time, we just noted it and wondered quietly if there was a way to help. I reached out to Michelle Sleiter, CEO to see if HCMH needed help. At the time, she indicated HCMH was monitoring the situation and following CDC and UnityPoint guidelines, but they had adequate supply at that point. I let her know that we had a sewing department at Hy-Cap and she should keep us in mind if they get to a point that they needed help.

A week or so later, Michelle reached out and asked about our capacity to make masks. She said she wasn't ready for us to start making them, but just needed to know if/how we could help them out. We gathered our experts to explain the situation and asked if we could make masks. Chad Vaudt, Cab Interior Supervisor and Sherri Hansen, a 20+ year veteran, looked at the patterns that Michelle had sent us and quickly nodded that yes, we could easily make them. We had plenty of sewing experts and plenty of people willing to help, all we needed was a few supplies. We went to V&S Variety and Jim and Joyce helped us find the materials we needed to make a few samples for HCMH to try.

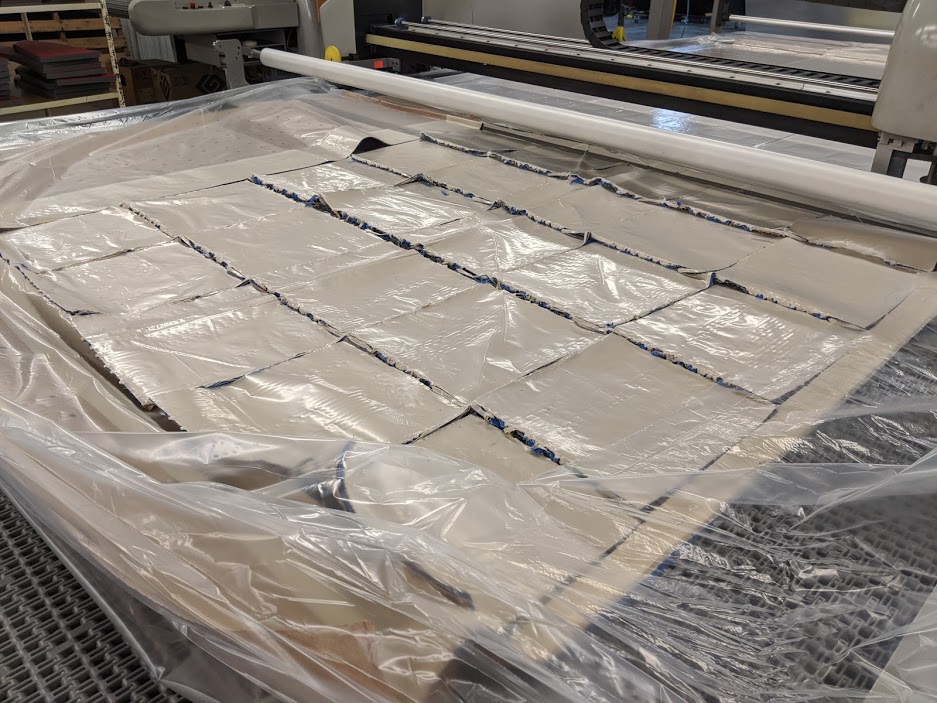

We made a few samples, but we were still kind of struggling with what to use for a nose piece. It needed to be flexible, washable, and be something we could somehow sew into place. We tried a variety of things that weren't perfect, a pipe cleaner, paper clip, we looked online for ideas, but we were stumped. We pretty much had everybody in the plant trying to come up with ideas. Finally, Steve Stalpes, Plant Manager, thought of a local resource who might have what we needed. Steve knew that Walt Jensen worked a lot with aluminum, so he took a sample piece down to Jensen Trailers to see if he had anything that might work. Walt took a quick look, went to work and gave Steve a stack of nose pieces that we could use. We were so excited! We had our patterns ready and digitized in our computerized cutter, we had our processes down and we knew that if or when the hospital needed our help, we'd be ready to go!

A few days later, Michelle contacted us to see if we could also take a look at making gowns. We said we'd sure give it a try. Our sewing experts took one look at the sample gown and again said, yes, we can sew them, we just needed materials. While we worked on creating a gown sample for the hospital to review, we started searching for bulk material and other supplies to have on hand just in case they needed us to get started in a hurry. We gave the hospital our sample gown and breathed a huge sigh of relief when they told us it was perfect for what they needed! We have some pretty perfectionist-type sewing experts and we were struggling to find the right balance between creating a masterpiece with the high level of detail that we spend on our seats and cab kits and focusing on getting a high volume of gowns and masks that needed to protect and be able to be washed and reused multiple times.

We now have all our materials and supplies in place and have begun production. We have dedicated several of our staff and resources to producing masks and gowns for HCMH and possibly other medical facilities that need help. We should give a special thanks to our Seat and Cab Kit team as they are juggling regular production needs for our busy season and also working so hard to do our part in making PPE. We have discussed what it looks like if we get to a point of needing to completely shift our focus to making PPE and we are mentally prepared to do that if the need arises.

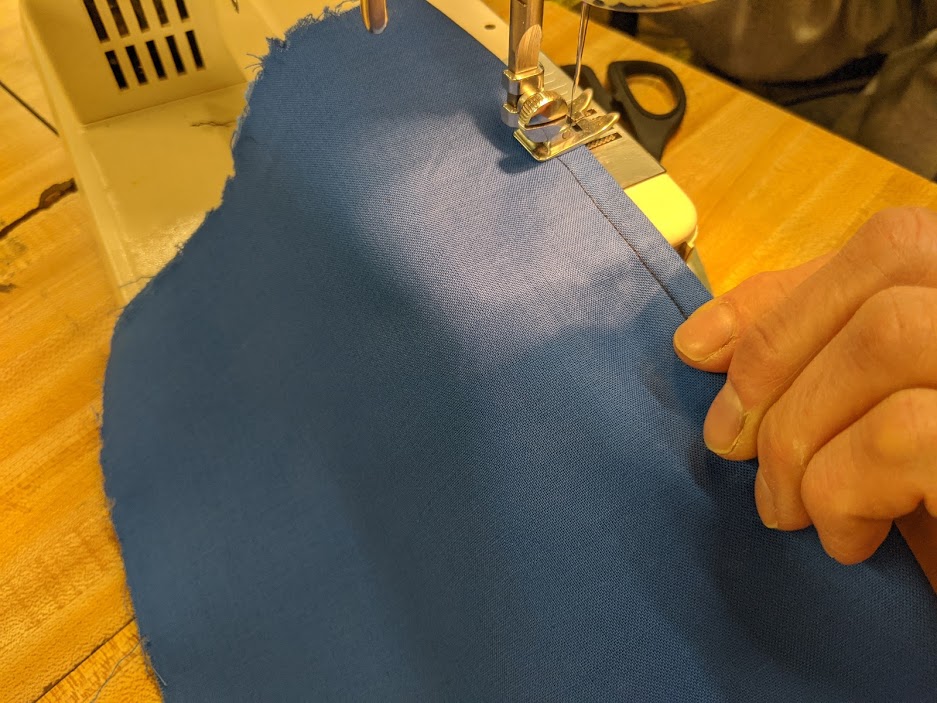

It has been so awesome to see our team members stepping up with such eagerness to help. Some of our equipment was too heavy duty for the lighter fabric needed for masks and gowns. We had several people offer to bring their own sewing machines from home. We have had several others ask if their mom, aunt, wife, friends could help sew masks, so we put together kits for people to take home and sew. We provided material, elastic, a nose piece and sewing instructions. In addition to the masks we’ve sewn at Hy-Cap, we’ve had nearly 200 additional masks made by volunteers. What a great community we live in!

_________________________________________________________________________________________

HCMH would like to thank everyone that has joined us the in fight against COVID-19 by making masks and gowns for our staff on the frontlines. "This community effort warrants an unwavering amount of thanks and makes our staff proud to be a part of such a giving and united community. As our organization continues to adjust to the COVID-19 outbreak we here at HCMH are ramping up our efforts to ensure uninterrupted care for those who count on us. While healthcare facilities across the nation face limited supplies of personal protective equipment (PPE), we are grateful for our local resources that have taken a great deal of the stress off our supply need and are ensuring our caregivers are protected. Our utilization rate is increasing dramatically, so we are continuing to follow CDC guidelines to conserve the disposable PPE and we have implemented a PPE conservation and reprocessing initiative." Michelle Sleiter, CEO

What has been most amazing is the response we have received for so many in the community asking how they can help. The kindness and generosity from the individuals, businesses and organizations is truly overwhelming. For those that are looking for ways to help, we are still accepting community donations of the following items:

• Masks, *specifically manufacturer-grade N-95 and surgical masks

• Goggles

• Monetary Donations for Emergency Preparedness Equipment and PPE https://www.humboldthospital.org/news-events/face-mask-donations-and-pattern

To make a donation please contact Mardi Ratzlaff, Foundation Director at 515-332-4200 or drop off at the main entrance, please call before you arrive.

Front Left to Right: Sherri Hansen, Anthony Christopherson, Claire Varangkounh, Macey Varangkounh, Lona Wilson

Back Left to Right: Scott Dahl, Denny Vaudt, Chad Vaudt, Barb Boyington, Brandi Beseke

Not pictured, but also helpful: Terri Hagge, Randy Stoneburner, All other Hy-Cap team members

THANK YOU HY-CAPACITY! Left to Right: Amie Larson, Radiology Tech, Tammy Kampen, Radiology Tech, Angela Guy, Radiology Tech and Stacy Clarken, Radiology Director

The Process:

Take-Home Mask Kit

Brandi Beseke, 20+ Year Hy-Capacity Employee sewing masks in their production room.

Victor Bycroft, Chief Nurse Executive modeling the gowns made by the Hy-Capacity team.